Contents:

Cyber, trolley or cradle? Naming and the DIN 9797 standard for tippersWhy do “cheap” trolleys break on welds? failure anatomyStuffing trolleys and stainless cymbers – manufacturer’s offerHygiene and HACCP – why does the weight and smoothness of welds matter?How to choose the capacity of the trolley for the production line?Paper will accept any price – production will verify the qualityCyber, trolley or cradle? Naming and the DIN 9797 standard for tippers

The linguistic ‘Tower of Babel’ prevails in production halls throughout Poland. The old butchers are shouting about the ‘cymber’, the warehousemen enter the ‘stainless cart’ system, and in some regions we will hear about the ‘colleb’. However, for a maintenance engineer and – most importantly – for your pole tipper, the name has no meaning. Only geometry matters.

Many entrepreneurs make a costly mistake when they commission local locksmiths without any experience in the food industry. effect? The stroller looks like a ‘two hundred’, but differs by 5 millimeters at the side handles (the so-called ears).

Here comes the key standard: DIN 9797.

It is she who defines the standard of ‘Euro-trolley’ (Euro-Bin). Whether you call it a cymbr or a stuffing trolley, the product must meet rigorous dimensions to be compatible with loading devices (wolves, mixers, stuffers).

If the trolley does not follow the DIN 9797 standard:

- The tipper will not ‘grab’ the truck stably: the risk of a fall of 200 kg of load on the floor (or employee).

- Wheel locking: Incorrect wheelbase will prevent access to the loading platform.

- Cover problems: Standard plastic or steel covers will not fit on the distorted edge.

in P.P.H.U. We do not recognize ‘approximate dimensions’. Each of our trolleys – from 120 l to 300 l – is calibrated for automatic production lines. When you buy a ‘cybra’ from us, you can be sure that your tipper (regardless of whether it is a chick, velati or another brand) will serve it without grinding.

Why do “cheap” trolleys break on welds? failure anatomy

When we hear from customers: ‘The competition has a cymbra 15% cheaper’, we usually ask one question: how much does this stroller weigh?

In the metallurgical industry, miracles do not exist. The price of the stuffing trolley is 80% due to the price of the material and the man-hour of the welder. A cheap stroller (often imported from the Far East) looks identical only in the photo in the catalog. In the production hall, the differences come out after the first 3 months of intensive use in a humid and saline environment.

Sin 1: Steel Uneven (1.4301 vs. Rest of the World)

The standard in the food industry is AISI 304 acid-resistant steel (1.4301). It is a material that is almost indestructible with proper maintenance. Cheap substitutes are often made of steel with reduced nickel content or thinner sheet metal (e.g. 1.5 mm walls instead of 2 mm). effect?

- The trolley under a load of 200 kg of meat begins to ‘work’ and deform.

- Fatigue microcracks appear.

- Plasma and brine accumulate in the crevices – an ideal environment for bacteria and corrosion that the Sanepid will not forgive.

Sin 2: A sensitive point – “ears” and edge

The critical moment in the life of every cymbra is a lifting by a tipper. The entire weight (cart + 200 kg of charge) rests on two side handles (‘ears’). In low-cost constructions, the ears are welded to the point or on the surface. In our company, we use full remelting of welds and additional reinforcements under the rim (reinforcement with a full rod, not a tube). Thanks to this, our carts withstand hydraulic jerks and impacts, which in weaker models break the handles, posing a deadly threat to the operation.

Sin 3: bottom and running gear – a weak link in the competition

The wheels in the butcher’s trolley are not easy. Crossings over the thresholds, drainage channels and throwing the trolley while washing is standard. The most common mechanical failure of cheap replacements is the breaking of the wheel mount from the thin bottom of the trolley.

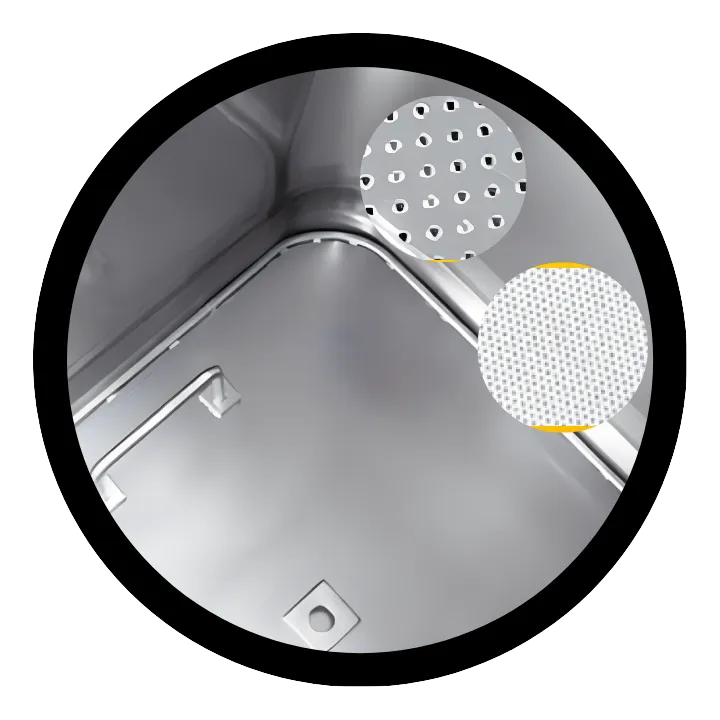

We do not use half measures. Our trolleys have a reinforced bottom with a total thickness of up to 5 mm. This is a unique sandwich design:

- 2 mm – specific wall of the trolley (acid-resistant steel 1.4301 / 1.4401).

- + 3 mm – additional reinforcing plate under the chassis.

Where others save on material, we create a rigid platform that will not bend under weight and blows. Conclusion: the trolley that breaks is not only about the cost of welding. This is the risk of foreign bodies (singles) in stuffing and line stoppage. By investing in a 5mm bottom, you buy peace for years.

Stuffing trolleys and stainless cymbers – manufacturer’s offer

Hygiene and HACCP – why does the weight and smoothness of welds matter?

The HACCP system in a meat plant does not end with documentation – it starts at the level of steel microstructure. for bacteria listeria or Salmonella Every scratch, leek in the weld or dent is a safe haven that will not be removed even by a pressure washer.

Why P.P.H.U. Tracz undergo sanitary audits without comments?

Smooth is safety (electropolating)

Most of the cheap carts are only digested with acid after welding. We go a step further. We subject our cymbry to the electropolishing process. It is not a matter of aesthetics (‘to shine’). It is a process that smoothes microscopic tops on the surface of steel, drastically reducing its porosity.

Effect: Bacteria and protein sediment have nothing to ‘catch’. The water flows faster and the consumption of washing agents drops.

Weight = dent resistance

We mentioned the thickness of the sheet (2 mm wall + 3 mm reinforcement). In terms of hygiene, the weight of the stroller is an advantage. A lightweight trolley made of thin sheet metal after a week of hitting the walls and other carts looks like a crumpled can. Each dent is a potential focus of stress corrosion and a place where dirt builds up. A solid, heavier stroller keeps the walls smooth for years, making it easy to disinfect.

Rolled Range Trap

The upper edge of the trolley is a critical place. Cheap manufacturers simply wrap the sheet metal, leaving an empty space in the middle or pointing it out of it. There, blood and water accumulate – a biological bomb. In our trolleys, the upper rim is reinforced with a solid Ø 14 mm rod, and then tightly welded along the entire length. A solid monolith is created – zero empty spaces, no risk of charge contamination.

Wheels that respect the clean zone

Hygiene is also a floor. Damaged, cracked floor in the butcher’s shop is a disqualification for auditing. That is why we use certified polyamide wheelsets. They are hard (low rolling resistance at 300 kg of load), but do not scratch the resin floors and are completely resistant to washing chemicals.

How to choose the capacity of the trolley for the production line?

In theory, the larger the trolley, the less frequently you have to run between the cutter and the stuffer. In practice – ‘oversizing’ of the rolling stock is the easiest way to problems with health and safety and damage to tippers.

in P.P.H.U. Tracz we produce a full range of capacity, but we advise our customers to choose based on production cycle analysisand not just price.

Trolley selection table (CYBRA)

Capacity | Typical load (meat) | best use | Operating Notes |

|---|---|---|---|

120 liters | approx. 80-100 kg | Small craft butchers, tight communication routes. Perfect for transporting spices, brine or as a waste trolley (confiscator). | Very easy to manually maneuver even for physically weaker employees. |

200 liters | approx. 160-180 kg | World Standard (DIN 9797). Universal choice for 90% of bets. Fits most standard pole tippers with wolves and mixers. | Optimal compromise between load capacity and ease of manual rolling. |

300 liters | approx. 240-260 kg | Large processing plants, continuous lines, transport between departments. Used where maximizing the charge in one cycle is important. | note: The full trolley weighs over 300 kg. We recommend using it on ideal floors or using electric tugs. Requires checking the lifting capacity of the tipper! |

Special carts: perforation

Perforated (punched) trolleys cannot be omitted. Although dimensionally compatible with the DIN standard (usually 200 L), they have a different function. is a solution dedicated to dripping processes (e.g. after brewing, washing vegetables) or thawing the raw material in cold stores. We offer Tracz versions with perforation of walls and bottoms, which ensures free air circulation and liquid outflow, while maintaining the armored strength of the frame.

The golden rule of selection

If your line is based on standard tippers (e.g. May, cane) and manual transport – Stay with the 200 l standard. It is the safest investment that guarantees full interchangeability of the rolling stock. If you plan to upgrade and automate transport – consider switching to the fleet 300 Lto reduce the number of logistics operations by 30%.

Paper will accept any price – production will verify the quality

In the tables in Excel, ‘The cheapest offer from the Internet’ always shines green and looks like the success of the purchasing department. However, in conditions of aggressive chemistry, moisture and everyday mechanical impacts, this apparent savings disappear quickly.

Choosing trolleys (cymbs) from P.P.H.U. Tracz, you are investing in something more than steel:

- Continuity of production: No downtime due to jamming of the distorted truck in the tipper.

- Peace of mind during audits: Smooth welds and certified 1.4301 steel are a guarantee of compliance with HACCP and IFS standards.

- longevity: Our carts have been working in plants in Europe and North America for decades, not one season.

We are not just an online store that imports containers. We are a producer from Wrocław with over 35 years of experience. We know how to weld steel so that it can withstand your pace of work, not just looking nice in the photo.